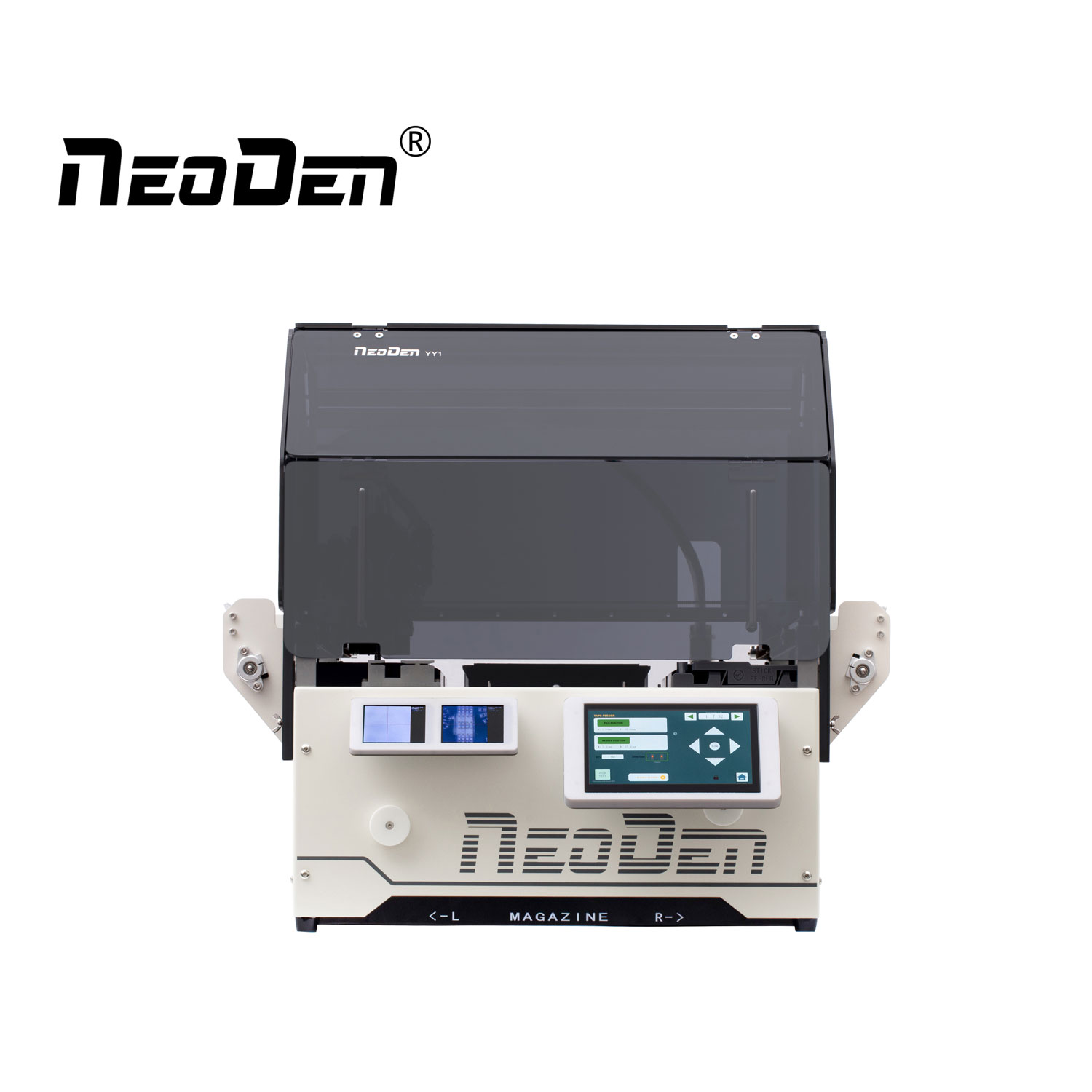

NeoDen YY1 Pick and Place Machine

Product Overview

Brand

Country/Region of Manufacture

PCB Applicable Dimension

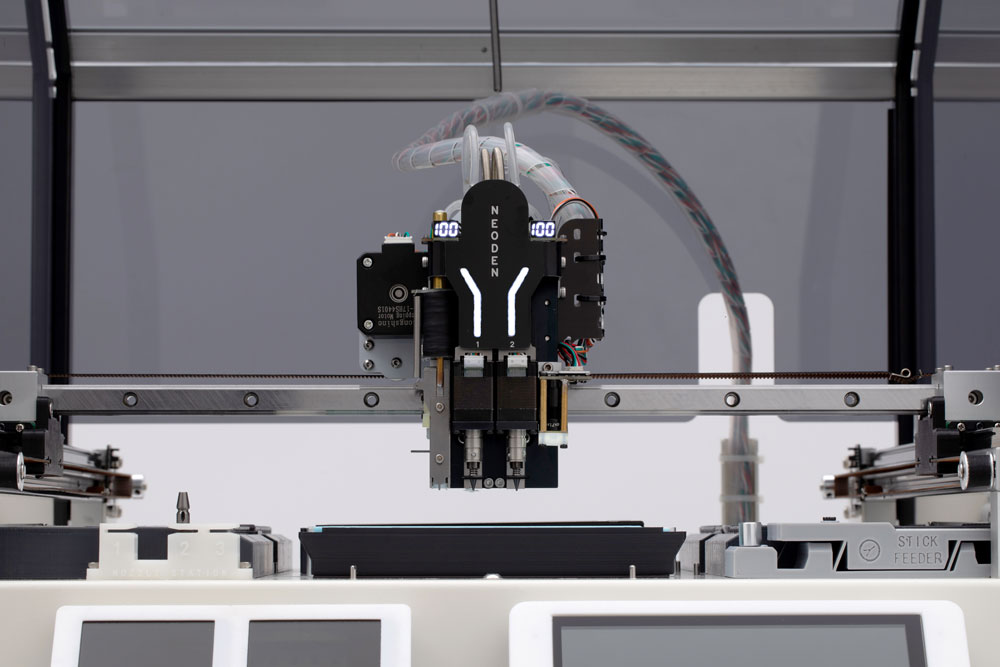

Head

Package dimension

Operation

NeoDen

China

(249~ 315)*350mm

Dual Head

700*610*600mm

Automatic

Model

Application

Speed

Smallest- largest size

Machine dimension

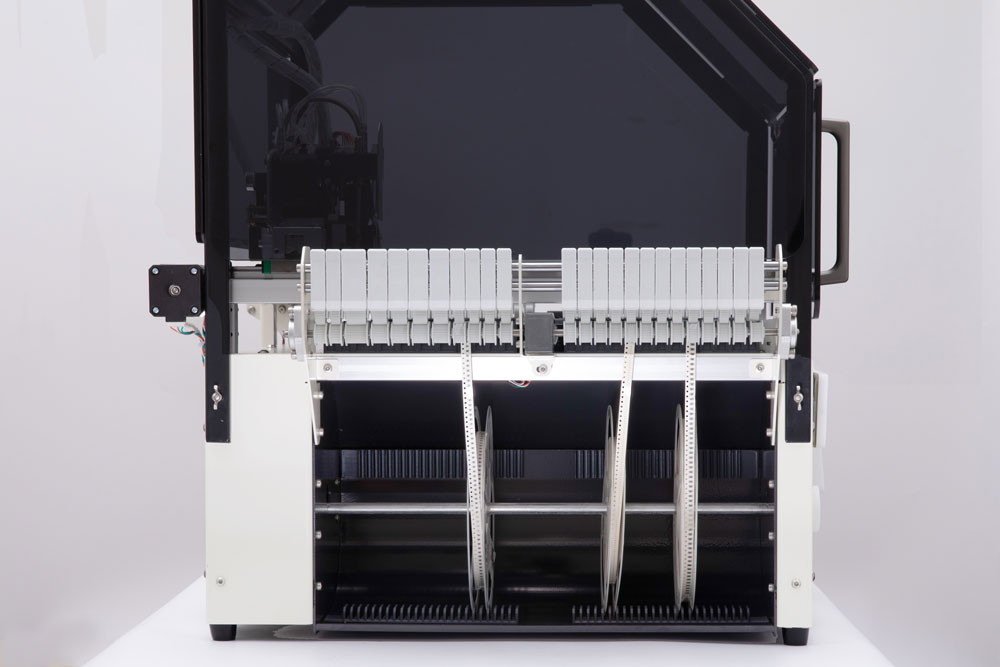

Tape feeder qty- standard

NeoDen YY1

PCB assembly prototype, SMT labs

3000- 4000CPH

0201- 18x18mm

643*554*601mm

36x 8mm; 6x 12mm; 3x 16mm

Description

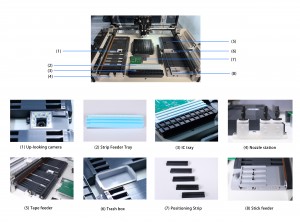

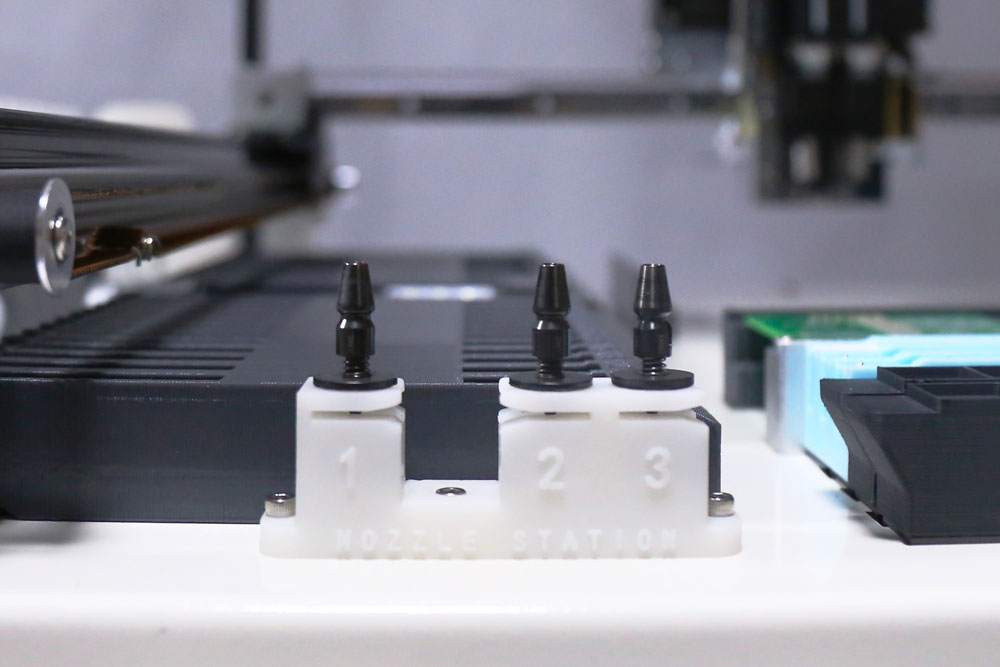

1. Automatic nozzle changer.

2. Independent high-definition & high-speed dual vision recognition systems.

3. Linear rail design for X, Y axis to ensure accuracy and stability.

4. Supports bulk component feeder, strip feeder and IC tray feeder.

5. Comes with a high-definition capacitive touch screen, which can be adjusted up and down.

| Machine Style | Single Gantry with 2 Heads |

| Alignment | Vision&Vacuum |

| Feeder Capacity | Tape Feeder: 52 (all 8mm), Stick Feeder: 4, Flexible Feeder: 28, Bulk Feeder: 19 |

| Nozzle Change Capacity | 3 Nozzles |

| Rotation | ±180° |

| Placement Accuracy | ±0.02mm |

| X-Y Repeatability | ±0.02mm |

| Z-axis Max Movement Range | 28mm |

| PCB Applicable Dimension | Maximum 249*350mm (dual sides tape feeder),Maximum 315*350mm (Single side tape feeder) |

| Electricity Supply | AC100V-240V |

| Software System | Independent Development |

| Control System | One-board Integration |

| Drives System | Stepper Motor |

| Positioning System | Fiducial Mark |

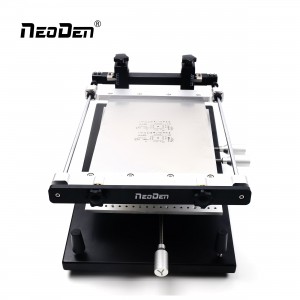

| PCB Handing | Manual PCB Loading/Unloading |

| Power | 50W |

| Weight | N.W.: 35.5kgs, G.W.: 47kgs (wooden box) |

Advantage and Highlights

Newly designed software system & UI for visual programming and placement, which allows fast programming on the machine, friendly interface & easy operation.

Automatic nozzle changer help realizing nozzles changed flexibly.

Supports bulk component feeder, strip feeder and IC tray feeder.

Our Service

Provide product instructions

YouTube video tutorials

Experienced after-sales technicians, 24 hours online service

With our own manufactory and more than 10 years of experience in SMT industry

We can provide customers with the most cost-effective products.

Package & Shipping

What Our Customers Say about YY1 Pick and Place Machine?

"It's actually much more intuitive to program and use.

The 3D printed parts are of very good quality and seem to have great layer adhesion."

"We bought a Neoden4 when they were still pretty new and now also jumped on a YY1 as a backup machine.

YY1 arrived quickly and setup was pretty easy.

If you are looking for shorter feeder setup time and higher accuracy you have to invest quite a bit more. For prototyping the YY1 is the right choice and I'm sure we will have some fun with it."

About Us

Factory

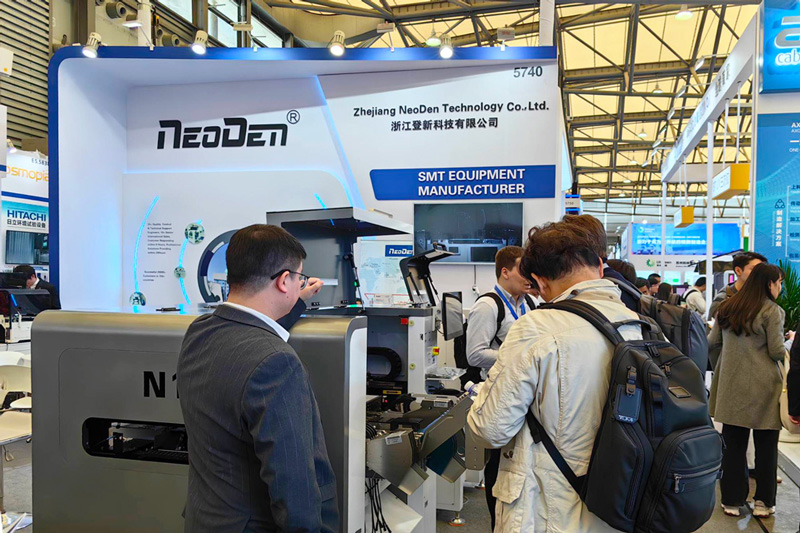

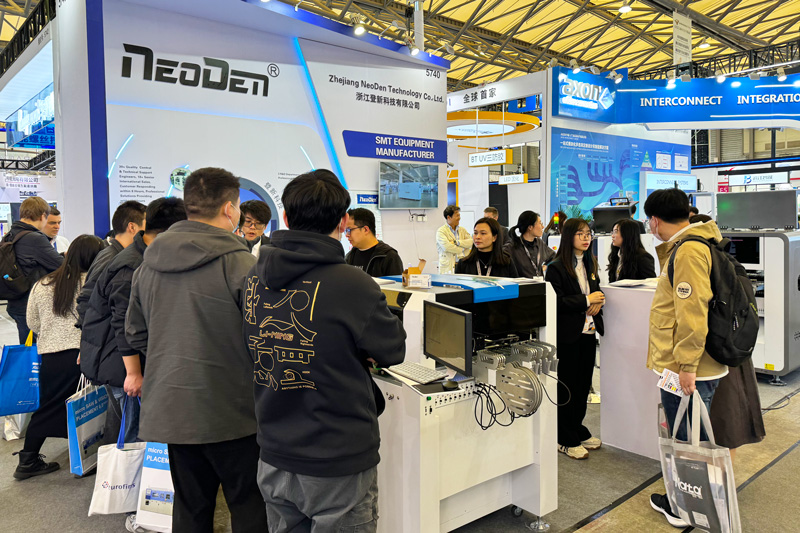

Exhibition

Certification

FAQ

Q1. How can I buy NeoDen YY1 pick and place machine from you?

A. 1. Consult us on line or by E-mail.

2. Negotiate and confirm the customized SMT line, final price, flexible payment method, delivery time, shipping and other terms.

3. Send you the proforma invoice and confirm your order.

4. Make the payment according to the method put on proforma invoice.

5. We prepare your order in terms of the proforma invoice after confirming your full payment. And 100% quality check the SMT machine before shipping.

6. Send your SMT equipments via express or by air or by sea.

Q2. Is it hard to use NeoDen YY1 pick and place machine?

A. No, not hard at all.

There are English manual and guide video that show you how to use NeoDen YY1.

If there is any doubt in the process of operating the YY1, please feel free contact us.

We also provide overseas on-site service and life time after-sales online support.

Q3. How about the warranty?

A. We support 2 years warranty of NeoDen YY1 pick and place machine. We will help you in time.

All the spare parts will be provided free of charge for you within the warranty period.

Q4. Are you trading company or manufacturer?

A. We are professional manufacturer specialized in SMT equipments.

We warmly welcome your arrival, before you take off from your country, please let us know.

We will show you the way and arrange time to pick you up if possible.

Q5. What about the lead time for prototyping SMT production line?

A. Honestly, it depends on the machines quantity.

Always 7-15 days based on general order.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.